The purpose of this document is to show how to recondition invoices in Autosoft.

1. Make the part that you will recondition

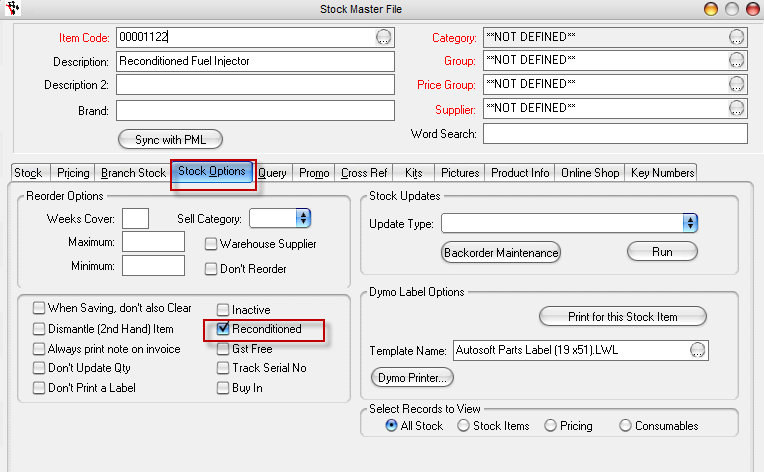

- Go to Stock Master File

![]()

- Create the Item (same details as creating a normal part, This is the details the Recon Part/Engine will be sold as)

- Go to Stock Options tab

- Tick Reconditioned

- F2 to Save

- Restart Autosoft

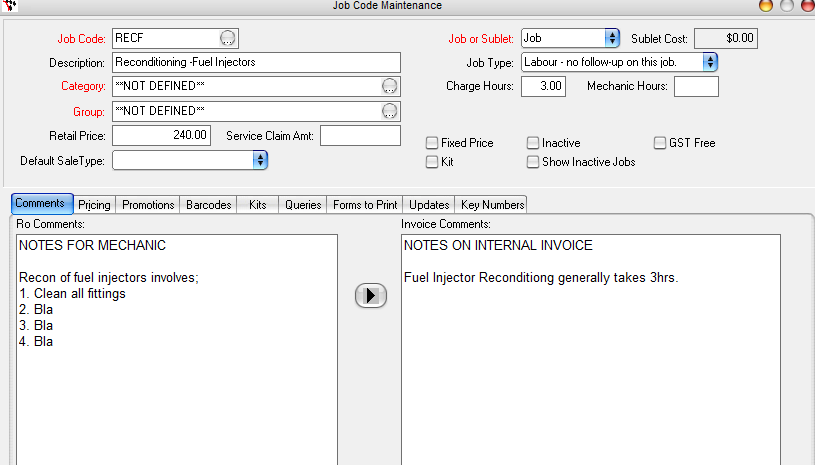

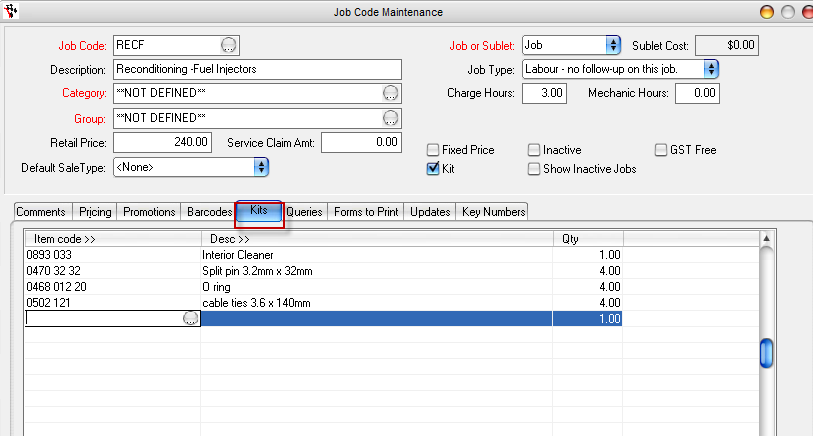

2. Check/Set up Job Code for Reconditioning Labour

- Go to Workshop - Job Codes

- The may be a default 'Reconditioning' Job Code you can use OR you may want to create a whole new Job Code for Labour for each Recon Type

e.g I want to have a Recon Job Code for all Fuel Injector Rebuilds as they will generally include the same amount of labour

and I have added all the Parts to the Kits tab as I will need the same core Parts for this type of Recon

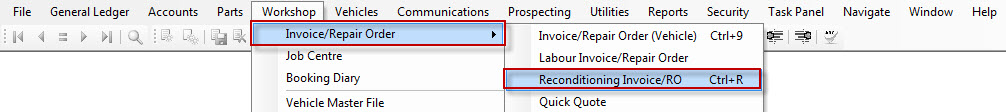

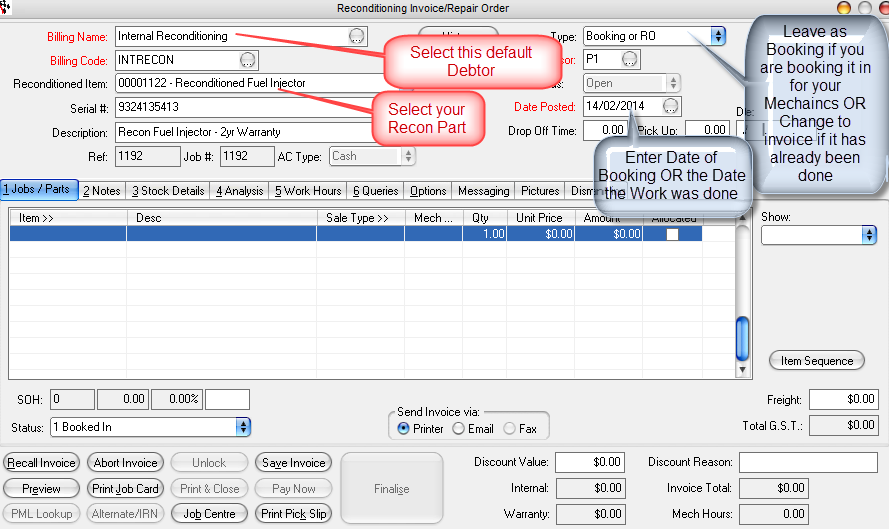

3. Create Booking/RO or Invoice for the work done to build the Reconditioned Part/Engine

- Enter the Invoice Header details;

- Billing Name - Internal Reconditioning (the pricing structure and default sales type are different to a normal debtor)

Use the pre-set Debtor called; "91 – Internal/ Staff"

- Reconditioned Item - Go to drop down menu - Product that was created in stock master file & Job Code

Note: Once Autosoft was restarted the product will appear on the list

- Serial # - Optional. You can enter a Serial Number for the Recon Part/Engine

- Type - Booking/ RO (if you are booking in the work) or Invoice (if you have already done the job)

- Advisor - Who it’s for and made by

- Date posted - What date

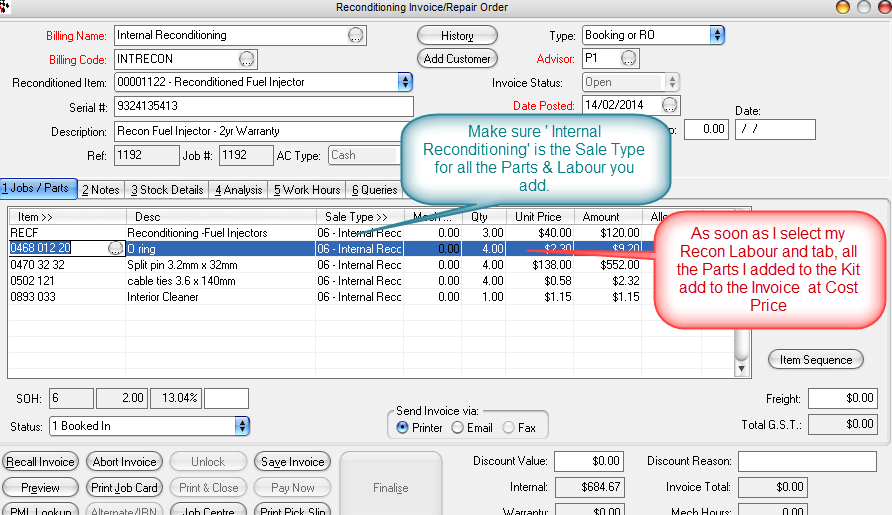

- Enter all the Labour and Parts needed for the Recon

- Job/ Parts tab - Pick up the “Labour” the Job Code you created for this reconditioning part

- Qty - important you enter how many you are making- message will pop-you say Yes

- Workshop Sale Type - Make sure this is set to the type 'Internal Reconditioning'

- Unit Price - This should be the COST price of the Parts & Labour

Note: Components are added to Job Card and system knows to multiply the Qty’s if your Labour Line Qty is more than 1.

Prices for parts are cost price = Average cost in stock master file

- This Booking will be in Booking Diary and Job Centre for you to keep track of it as you work on it (like a normal Workshop invoice)

- Add the Labour Time to the Recon Inv- Hours tab (As many mechanics you want)

- Finalise = Internal $$$ Finalise like normal Invoice

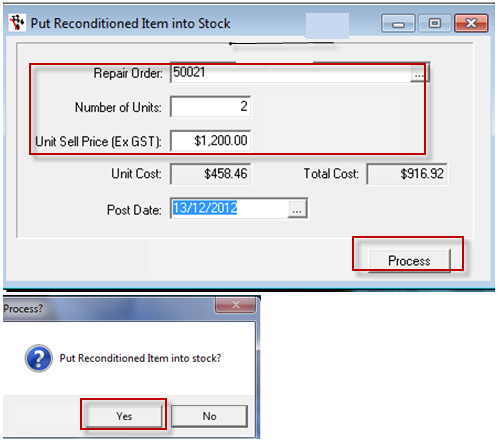

4. Add Reconditioned item into stock

- Go to Workshop- Add Reconditioned item to stock

- Repair Order – Find the Recon repair order that was done

- Number of Units - how many you made

- Unit Sell Price = Enter the price you wish to sell the part/engine at.

- Click Process

- Message pop up click Yes and OK to items added to stock

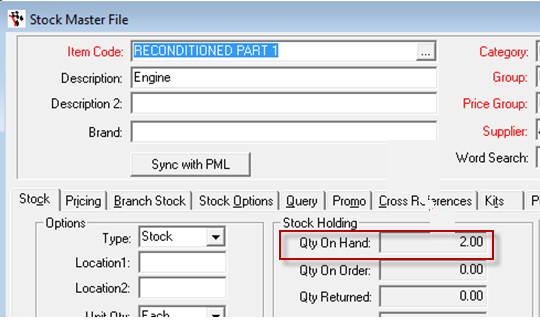

- The Recon item will now be available in the Stock Master File.

Note: The Qty on hand changes from this being added from “add reconditioning item to stock” screen

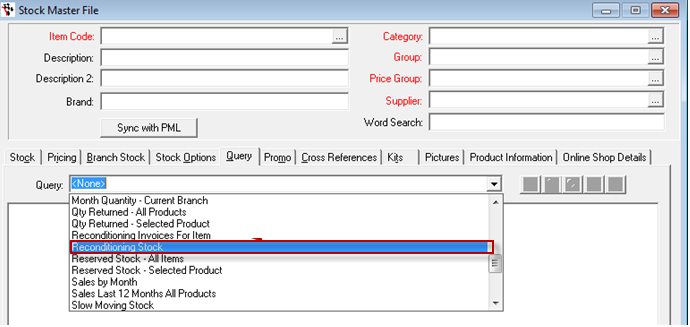

- This can now be sold over like any of your normal parts - you can keep track of it in the Stock Master File and by running the Query 'Reconditioning Stock' to see history

5. Multiple Recon Parts that make Up a whole Kit/Engine

If you have additional Recon components that all add to the one Recon Engine = Follow the same procedure as above and once all Recon Items are in Stock , Setup the Recon Engine as a Job Code Kit.http://service.autosoft.com.au/entries/21415145-How-to-Create-a-Job-Code-Kit- then follow the above process again.

22 Comments